Advantages and disadvantages of sewage pumps

1、 Overview of sewage pumps:

Sewage pump belongs to a type of centrifugal pump impurity pump, which has various forms, such as submersible and dry. The most commonly used submersible is the QW submersible sewage pump, and the most common dry sewage pump is the W horizontal sewage pump and the WL vertical sewage pump.

Mainly used for transporting urban sewage, feces or liquids containing solid particles such as fibers and paper scraps, the temperature of the transported medium is usually not greater than 80 ℃.

Due to the presence of fibers that are prone to entanglement or bunching in the medium being transported. Therefore, the flow channel of this type of pump is prone to blockage. Once the pump is blocked, it will not work properly, and even burn out the motor, resulting in poor drainage.

It has a serious impact on urban life and environmental protection, therefore, anti clogging and reliability are important factors for the quality of sewage pumps.

2、 Classification of sewage pumps:

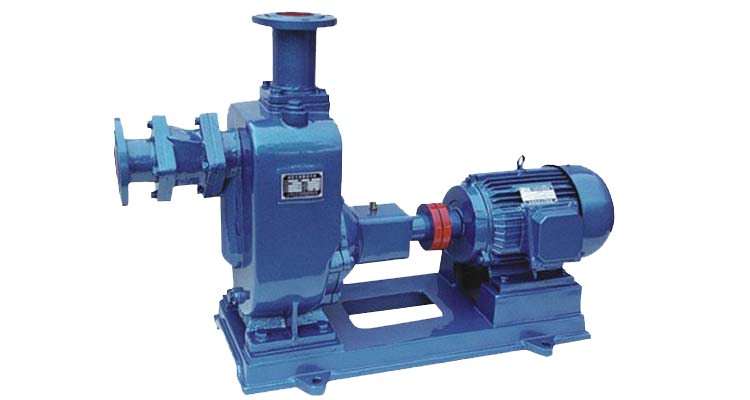

Sewage pumps can be divided into: submerged sewage pumps, pipeline sewage pumps, submersible sewage pumps, vertical sewage pumps, corrosion-resistant sewage pumps, acid resistant sewage pumps, and self-priming sewage pumps.

The models of sewage pumps include PW sewage pump and PWL sewage pump.

The most common type of pressure chamber used in PW sewage pumps is the volute, and radial guide vanes or channel type guide vanes are often used in internal submersible pumps.

The PWL sewage pump impeller and pressure chamber are the two core components of the sewage pump. The quality of its performance also represents the quality of the pump's performance.

With the progress of society, the continuous improvement of people's living standards, and the strengthening of environmental awareness, sewage pumps have become familiar to people and their application scope has become increasingly broad.

3、 Advantages of sewage pumps:

1. Compact structure with small footprint. The pump can be directly installed in the sewage tank due to its submerged operation, without the need to build a dedicated pump room to install the pump and motor, saving a lot of land and infrastructure costs.

2. Easy installation and maintenance. Small submersible sewage pumps can be freely installed, while large sewage pumps are generally equipped with automatic coupling devices for automatic installation, making installation and maintenance quite convenient.

3. Long continuous operation time. Due to the coaxial connection between the pump and motor, the shaft of the submersible sewage pump is short, and the weight of the rotating parts is light, the load (radial) borne on the bearings is relatively small, and the service life is much longer than that of ordinary pumps.

4. Low vibration noise, low motor temperature rise, and no pollution to the environment.

4、 The characteristics of sewage pumps:

1. Adopting advanced technology, with strong discharge capacity and no blockage, it can effectively pass through solid particles with a diameter of ∅ 30- ∅ 80 millimeters.

2. The tearing mechanism can tear, cut, and smoothly discharge the fibrous material without the need for a filter screen on the pump.

3. Reasonable design, low matching motor power, and significant energy-saving effect.

4. The use of the latest material mechanical seal can ensure safe and continuous operation of the pump for over 8000 hours.

5. Compact in structure, easy to move, easy to install, can reduce project costs, and does not require the construction of a pump room.

6. Can be used within the full head range while ensuring that the motor does not overload.

7. The floating ball can automatically control the start and stop of the pump according to the required water level changes, without the need for dedicated personnel to monitor.

8. The double guide rail automatic installation system brings great convenience to installation and maintenance, and people do not need to enter or exit the sewage pit for this.

9. Equipped with a fully automatic protection control box, it effectively protects the product from electric leakage, water leakage, and overload, improving the safety and reliability of the product.