This article is enough to analyze the types and common faults of water pumps

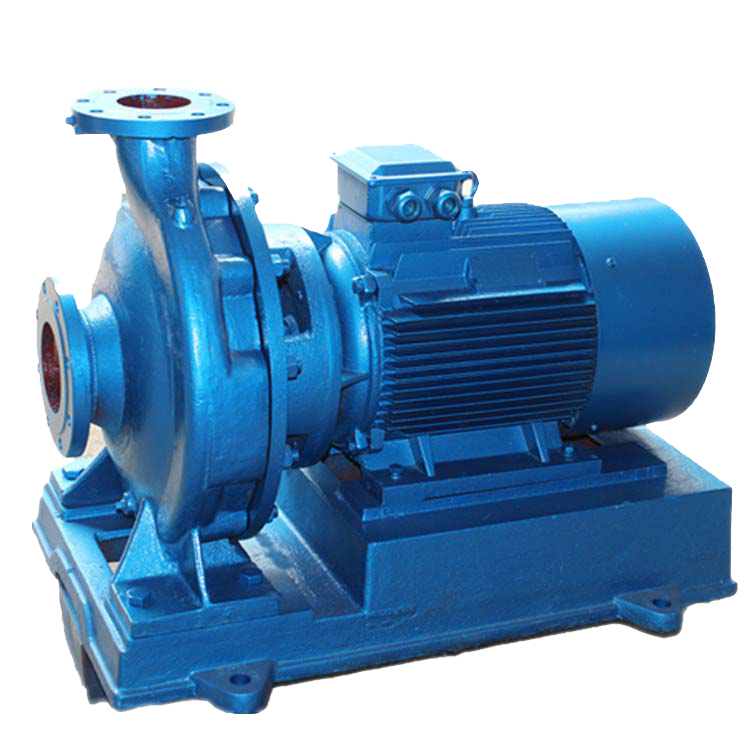

A water pump is a mechanical device that transports or pressurizes liquids.

It transfers the mechanical energy or other external energy of the prime mover to the liquid, increasing the energy of the liquid. It is mainly used to transport liquids including water, oil, acid-base liquids, emulsions, suspensions, and liquid metals. It can also transport liquids, gas mixtures, and liquids containing suspended solids.

Water pumps are an important general-purpose machinery with a wide range of types and uses, playing an extremely important role in the economy. Wherever liquid passes through, there will be water pumps working.

Nowadays, there are about 2200 types of pumps in China, and even more than 5000 types abroad. The technology of water pumps has developed to a relatively high level, and there are also many methods for classifying these pumps.

Next, Guangzhou Quanyi Pump Industry Co., Ltd. will introduce several commonly used pump classification methods and pump types.

1、 Classified by working principle:

1. Vane pump

1.1 Vane pumps can be divided into centrifugal pumps, mixed flow pumps, axial flow pumps, and vortex pumps.

1.2 Centrifugal pumps: single-stage centrifugal pumps (single suction single-stage centrifugal pumps, double suction pumps, self suction pumps, non self suction single-stage centrifugal pumps), multi-stage centrifugal pumps (segmented multi-stage centrifugal pumps, vortex multi-stage centrifugal pumps).

1.3 Mixed flow pump: volute pump, guide vane type (fixed blade, adjustable blade).

1.4 Axial flow pump: fixed blades, adjustable blades.

1.5 Vortex pump: single stage vortex pump, double stage vortex pump, self suction vortex pump, non self suction vortex pump.

2. Positive displacement pump

2.1 Positive displacement pumps can be divided into: reciprocating pumps, plunger pumps, rotor pumps, diaphragm pumps, and screw pumps.

2.2 Reciprocating pump: piston pump (single cylinder, multi cylinder).

2.3 Plunger pump: (single cylinder, multi cylinder).

2.4 Rotary pump: gear type (internal meshing).

2.5 Diaphragm pump: (pneumatic, electric, hydraulic).

2.6 Screw pump: (single, double, triple screw).

3. Other types of pumps

Jet pump, water hammer pump, gas lift pump, sliding vane pump, Roots pump, roller pump, liquid ring pump, peristaltic pump, cam pump, water turbine pump, and electromagnetic pump, etc.

2、 Classified by purpose

Delivery pumps, circulation pumps, fire pumps, pressure testing pumps, sewage pumps, metering pumps, sanitary pumps, dosing pumps, gelatinization pumps, infusion pumps, defoaming pumps, process pumps, oil transfer pumps, water supply pumps, drainage pumps, drainage pumps, dredging pumps, sprinkler pumps, booster pumps, high-pressure pumps, high-temperature pumps, etc.

3、 Classified by industry

Petroleum pumps, metallurgical pumps, chemical pumps, oil industry pumps, mining pumps, electric pumps, water conservancy pumps, water treatment pumps, food pumps, brewing pumps, pharmaceutical pumps, beverage pumps, refining pumps, seasoning pumps, papermaking pumps, textile pumps, printing and dyeing pumps, pottery pumps, paint pumps, pesticide pumps, fertilizer pumps, etc.

4、 Classification by conveying medium

Clear water pump, sewage pump, seawater pump, hot water pump, hot oil pump, viscous oil pump, oil pump, heavy oil pump, residue pump, asphalt pump, impurity pump, slurry pump, mortar pump, mortar pump, ash pump, mud pump, cement pump, concrete pump, powder pump, acid alkali pump, air pump, steam pump, oxygen pump, ammonia pump, gas pump, etc.

Which brand is good for choosing a water pump?

Our country has achieved impressive results in the development of the four modernizations to this day, which has given rise to many well-known brand manufacturers of water pumps. When choosing a suitable water pump, only the following principles need to be installed to select a more reliable water pump brand.

1. Identify legitimate water pump manufacturers

When choosing a water pump, it is best for users to go to a sales point recognized by the agricultural machinery department, and be sure to recognize the legitimate manufacturer.

Never purchase products without a manufacturer, production date, or production license. Otherwise, if problems arise, users will be at a loss.

As a water pump user, due to the limitations of professional knowledge, it is difficult to determine the quality of the water pump. The best way is to consult experts in the field of water pumps. It is also advisable to consult some old water pump users, especially those with similar usage conditions. Purchasing products that users trust, have reliable quality, and are relatively mature can be a wise choice.

Meanwhile, the decision to use a single-phase pump or a three-phase pump should be based on the local power supply situation.

2. Choose a water pump that meets the head requirements

The so-called head refers to the required head, not the lifting height, which is particularly important for selecting a water pump.

The head of the water pump is approximately 1.15-1.20 times the lifting height. If the vertical height from a certain water source to the water point is 20 meters, the required head is approximately 23-24 meters.

When selecting a water pump, it is best to ensure that the head on the pump nameplate is close to the required head, with a general deviation of no more than 20%. In this case, the efficiency of the water pump is the highest, and it is also more energy-saving, making it more economical to use.

If the head on the nameplate is much smaller than the required head, the water pump often cannot meet the needs of the user. Even if the water can be pumped up, the amount of water is pitiful.

But on the contrary, when high head water pumps are used for low head, excessive flow will occur, leading to motor overload. If the motor is operated for a long time, the temperature will rise, and the insulation layer of the winding will gradually age, and even burn out the motor.

3. Choose a water pump with appropriate flow rate

The flow rate of the water pump, that is, the water output, should generally not be too large, otherwise it will increase the cost of purchasing the water pump. It should be selected according to the needs, such as the self priming water pump used by the user's household, and the flow rate should be selected as small as possible; If users use submersible pumps for irrigation, they can choose pumps with higher flow rates appropriately.

4. The key to selecting agricultural water pumps

4.1 Choose water pumps according to local conditions

There are three types of commonly used agricultural water pumps, namely centrifugal pumps, axial pumps, and mixed flow pumps.

The centrifugal pump has a higher head but a smaller water output, making it suitable for mountainous areas and well irrigation areas.

The axial flow pump has a large water output, but the head is not too high, making it suitable for use in plain areas;

The output and head of a mixed flow pump are between centrifugal pumps and axial pumps, and are suitable for use in plain and hilly areas.

Users should make purchases based on local conditions, water sources, and water lifting heights.

4.2 Choosing water pumps that exceed the standard appropriately

After determining the type of water pump, its economic performance should be considered, with special attention paid to the selection of the pump's head, flow rate, and supporting power.

It must be noted that there is a difference between the head (total head) indicated on the water pump label and the outlet head (actual head) during use. This is because there is a certain resistance loss when the water flows through the water delivery pipe and near the pipeline.

So, the actual head is generally 10% -20% lower than the total head, and the water output also decreases accordingly.

Therefore, in actual use, it can only be estimated based on 80% to 90% of the head and flow rate indicated on the label. The selection of the matching power of the water pump can be based on the power indicated on the label. In order to ensure the quick start and safe use of the water pump, the power of the power machine can also be slightly higher than the required power of the water pump, generally about 10% higher.

If there is already power, when purchasing a water pump, you can choose a matching water pump according to the power of the power machine.

4.3 Strict procedures are required for purchasing water pumps

When making a purchase, it is necessary to verify the "three certificates", namely the agricultural machinery promotion license, production license, and product inspection certificate. Only when the three certificates are complete can we avoid purchasing obsolete and inferior products.

Analysis of common faults in water pumps and corresponding solutions

1. The water pump cannot start

Firstly, check the power supply situation; Whether the joint connection is secure; Check if the switch contacts are tight; Is the fuse blown; Is the three-phase power supply lacking equality.

If there is an open circuit, poor contact, blown fuse, or missing phase, the cause should be identified and repaired in a timely manner.

Secondly, check if it is a mechanical failure of the pump itself. Common causes include: tight packing or blockage between the impeller and pump body due to debris; The pump shaft, bearings, and leakage reducing ring are rusted; The pump shaft is severely bent, etc.

Exclusion method: Relax the filling and dredge the drainage channel; Disassemble the pump body to remove debris and rust; Remove the pump shaft for calibration or replace it with a new one.

2. Heating of water pump

2.1 Bearings

Reason:

1) Damage;

2) The clearance between rolling bearings or bracket covers is too small;

3) The pump shaft is bent or the two shafts are not concentric;

4) The tape is too tight;

5) Lack of oil or poor oil quality;

6) The balance hole on the impeller is blocked, causing the impeller to lose balance and increasing the thrust to one side.

Exclusion method:

1) Replace bearings;

2) Remove the rear cover and install a gasket between the bracket and the bearing seat;

3) Investigate the pump shaft or adjust the concentricity of the two shafts;

4) Adjust the tightness of the tape appropriately;

5) Add clean butter, which accounts for about 60% of the clearance inside the bearing;

6) Remove blockages from the balance hole.

2.2 Insufficient traffic.

Reason: Power speed mismatch or belt slipping, resulting in low speed; The installation angle of the axial flow pump blades is too small; Insufficient head, too long pipeline or right angle bend in the pipeline;

High suction head: Local blockage or impeller defect in the bottom valve, pipeline, and impeller; The water outlet pipe is leaking severely.

Troubleshooting method: Restore the rated speed, remove oil stains from the belt, and adjust the belt tightness; Adjust the blade angle, lower the installation position of the water pump, shorten the pipeline or change the curvature of the pipeline;

Seal the leak of the water pump and tighten the packing; Remove blockages and replace impellers; Replace the leak reducing ring and block the leaking area.

2.3. Unable to absorb water.

Reason: There is air inside the pump body or air accumulation in the inlet pipe, or the bottom valve is not tightly closed, the water supply is insufficient, the vacuum pump packing is severely leaking, and the gate valve or flap door is not tightly closed.

Troubleshooting method: First increase the water pressure, then fill the pump body with water, and then turn on the machine.

At the same time, check whether the check valve is tight and whether there is any air leakage in the pipelines and joints. If any air leakage is found, apply lubricating oil or blending paint to the joint after disassembly, and tighten the screws.

Check the oil seal ring of the water pump shaft. If it is severely worn, replace it with a new one. Pipeline leaks water or air. The nut may not be tightened tightly during installation.

If the leakage is not severe, cement can be applied to the leaking or leaking area, or cement slurry mixed with asphalt can be applied.

Temporary repairs can be done with damp mud or soft soap. If there is water leakage at the joint, a wrench can be used to tighten the nut. If the leakage is severe, it must be disassembled and replaced with a cracked pipe.

Reduce the head and press the nozzle of the water pump 0.5m underwater.

3. Severe vibration of water pump

There are several main reasons: unbalanced electric rotor; Poor coupling connection; Wear and bending of bearings; Loose or cracked rotating parts; Due to reasons such as loose pipeline supports.

Measures such as adjustment, repair, reinforcement, straightening, and replacement can be taken separately.

4. Pump matching power motor overheated

There are four reasons for this:

4.1 Power supply reasons.

If the voltage is too high or too low, under specific loads, if the voltage fluctuation range should be outside of+10% to -5% of the rated value, it will cause the motor to overheat;

Asymmetric three-phase voltage in the power supply, with a voltage imbalance between the three phases exceeding 5%, can cause overheating of the winding;

Lack of phase operation, experience has shown that over 85% of the burning of agricultural motors is caused by lack of phase operation. Therefore, it is necessary to install a lack of phase protection device for the motor.

4.2 Reasons related to water pumps.

The use of mismatched power, small horses pulling large vehicles, and prolonged overload operation of the electric motor result in excessively high motor temperature;

Electric motors that start too frequently and have a rated short-term or intermittent working system operate continuously. The number of starts should be limited, thermal protection should be selected correctly, and used according to the rated values specified on the motor.

4.3. The reason for the motor itself.

Connection error, mistakenly connecting the △ shape to the Y shape, causing the temperature of the motor to rapidly increase;

The stator winding has phase to phase short circuit, turn to turn short circuit, or local grounding. In mild cases, the motor may overheat locally, and in severe cases, the insulation may be burned out;

The squirrel cage rotor has broken bars or defects, and the motor runs for 1 to 2 hours, causing a rapid increase in core temperature;

If there is a malfunction in the ventilation system, it is necessary to check whether the fan is damaged, whether the rotation direction is correct, and whether the ventilation ducts are blocked;

Wear of bearings and eccentric cleaning of the rotor cause the iron cores of the stator and rotor to rub against each other and produce a metallic impact sound. The temperature of the iron core rapidly rises, and in severe cases, the motor may smoke or even the coil may be burned out.

4.4. Reasons related to work environment.

The motor winding is affected by moisture, dust, oil stains, etc., which attach to the winding, resulting in a decrease in insulation.

The insulation resistance of the motor should be measured and cleaned and dried;

The ambient temperature is too high. When the ambient temperature exceeds 35 ℃ and the inlet air temperature is high, it will cause the temperature of the motor to be too high. Efforts should be made to improve its working environment, such as setting up a shed for shading.

Attention: If a malfunction occurs due to electrical reasons, it should be repaired by an electrician who has obtained a professional qualification certificate. People with only a limited understanding should not blindly repair to prevent personal injury accidents.

5. The cavitation phenomenon of water pumps

The cavitation of a water pump is caused by the vaporization of water, which is the process of water transforming from liquid to vapor in a manual diaphragm pump.

The vaporization of water is related to temperature and pressure to a certain extent. At a certain pressure, water only begins to vaporize when the temperature reaches a certain value.

If the pressure drops to a certain value at a certain temperature, water will also vaporize, and this pressure is called the vaporization pressure of water at a different temperature.

If during the flow process, the pressure in a certain local area is equal to or lower than the vaporization pressure corresponding to the water temperature, water vaporizes at that location.

After vaporization occurs, many small bubbles of steam mixed with gas will be formed.

When bubbles flow with water from the low-pressure area to the high-pressure area, they rupture under the action of high pressure, and high-pressure water flows at an extremely high speed towards the space occupied by these original bubbles, forming an impact force.

The metal surface is severely damaged due to fatigue under water hammer pressure.

Therefore, we refer to the entire process of bubble formation, development, and rupture leading to material damage as cavitation phenomenon.

6. Analysis of the causes of water pump vibration

There are many reasons for the vibration of the unit and pump room building caused by the analysis of the causes of water pump vibration. Some factors have both connections and interactions, and can be summarized into the following four main reasons.

6.1 Electrical aspects.

The motor is the main equipment of the unit. The imbalance of magnetic force inside the motor and the imbalance of other electrical systems often cause vibration and noise in submersible pumps.

If the radial alternating magnetic pulling force between the stator and rotor is generated by the interaction of harmonic magnetic flux between the stator and rotor teeth during the operation of the abnormal motor, or if the magnetic center of the stator and rotor is inconsistent or the air gap difference in all directions exceeds the allowable deviation value during the operation of a large synchronous motor, it may cause periodic vibration and noise of the motor.

6.2 Mechanical aspect

The unbalanced quality, rough manufacturing, poor installation quality, asymmetric axis of the unit, excessive swing of the rotating components of the motor and water pump, poor mechanical strength and stiffness of the components, wear and damage of bearings and sealing components, as well as resonance caused by the critical speed of the water pump and the natural frequency of the unit, can all generate strong vibration and noise.

6.3. Hydraulic aspect.

Uneven flow velocity and pressure distribution at the inlet of the water pump, pressure pulsation, liquid flow, deviation and detachment at the inlet and outlet of the pump, non rated operating conditions, and pump cavitation caused by various reasons are common causes of unit vibration.

The rapid pressure changes and water hammer effects in the water supply pipeline caused by dynamic transition processes such as pump startup and shutdown, valve opening and closing, working condition changes, and emergency shutdown accidents often lead to vibration in the pump room and unit.

6.4 Hydraulic engineering and other aspects.

Unreasonable or mismatched design of the inlet channel of the water pump unit, improper submergence depth of the water pump, and unreasonable starting and stopping sequence of the water pump control valve can worsen the inlet conditions, generate vortices, induce cavitation or aggravate the vibration of the unit and pump room.

When using a unit that breaks the siphon vacuum to cut off the flow, if the air in the hump section is difficult to carry during startup, the siphoning time will be too long.

The design of the unit's flap door with flow interruption is unreasonable, opening and closing at times, constantly hitting the flap door seat; Uneven settlement or poor rigidity of the foundation supporting the water pump and motor can also cause vibration of the unit.

Common faults and maintenance methods of water pumps:

Pump maintenance should be based on the causes of pump malfunctions mentioned above, and it is generally not recommended for users to repair the pump themselves. They can contact the manufacturer's technician or entrust a professional pump maintenance company to repair the pump.

If it is a common minor malfunction, you can also seek technical personnel with experience in water pump maintenance for repair. Next, technicians from Guangzhou Quanyi Pump Industry will share some maintenance methods for key components of water pumps, hoping to be helpful to users.

1. Static balance of impeller

When the water pump rotor operates at high speeds, if the air mass is uneven, a large centrifugal force will be generated during rotation, causing vibration or damage to the water pump.

The balance of the rotor is achieved through the mass balance of various components on it (including the structural wheel, shaft sleeve, balance plate, etc. of the shaft and blade centrifugal pump). Therefore, static balance verification work should be carried out on newly installed impellers. The specific method is:

(1) Install the impeller on the dummy shaft and place it on a horizontally adjusted static balance test bench. There are two tracks on the test bench, on which the dummy axis can freely roll.

(2) Mark the side of the impeller that is biased. If the quality of the impeller is unbalanced, the heavier side always automatically turns downwards.

Add heavy blocks (using surface adhesive or clamps to add or remove iron plates) in the symmetrical position of the heavier part (i.e. the lighter side) until the impeller can stop at any position.

(3) Weigh the weight of the weighting block

Usually, we do not add weight on the lighter side of the impeller, but instead achieve balance by reducing weight on the heavier side.

When reducing weight, a milling machine or grinding wheel can be used (when the removal amount is not large), but it should be noted that the depth of milling or grinding should not exceed one-third of the thickness of the impeller cover plate.

After static balancing, the allowable deviation value of the impeller shall not exceed the product of the outer diameter value of the impeller and 0.25g/mm. For example, for an impeller with a diameter of 200mm, the allowable deviation is 5g.

2. Disassembly and assembly of couplings

(1) When disassembling the coupling, it is not advisable to directly hit it with a hammer. Instead, a copper rod should be used to pad it, and the water pump coupling at the hub of the coupling should be struck instead of the outer edge of the coupling, as it is prone to damage.

The most ideal way is to use a wrench to disassemble the coupling. For small and medium-sized water pumps, the coupling is easy to remove due to its small interference fit.

For larger water pumps, there is a significant interference fit between the coupling and the shaft, so the coupling must be heated during disassembly.

(2) When assembling the coupling, pay attention to the key number (for couplings with two or more keys).

When striking with a copper rod, attention must be paid to the striking area.

For example, when tapping the end face of the shaft hole, it is easy to cause the shaft hole to shrink, so that the shaft cannot pass through.

When tapping the outer edge of the wheel, it is easy to damage the flatness of the end face, and using a feeler gauge to align it in the future will affect the accuracy of the measurement.

For couplings with large interference, they should be heated before installation.

(3) The coupling pins, nuts, washers, and gaskets must ensure their respective specifications and sizes are consistent to avoid affecting the dynamic balance of the coupling.

Corresponding markings should be made on the coupling bolts and corresponding coupling pin holes to prevent incorrect installation.

(4) The fit between the coupling and the shaft generally adopts a transitional fit, which may result in a small amount of interference or clearance. For couplings with longer wheel hubs, a looser transitional fit can be used. Due to the longer shaft holes, rough and uneven surface processing will naturally produce partial interference after assembly.

If it is found that the fit between the coupling and the shaft is too loose, which affects the concentricity of the hole and shaft, repair welding should be carried out. Punching spots or padding with copper on the shaft is a temporary measure and cannot be an ideal method.

The meaning and calculation method of technical parameters such as water pump flow rate, head, power, and cavitation margin:

1. Traffic Q

Flow rate refers to the amount of liquid (volume or mass) transported out per unit of time. The volumetric flow rate is expressed in Q, and the unit is: m ³/ s. M ³/ h. I/s, etc.

The mass flow rate is expressed in Qm, with units such as t/h, kg/s.

The relationship between mass flow rate and volumetric flow rate is:

Qm= ρ Q

In the formula ρ—— Density of liquid (kg/m) ³, T/m ³), Clear water at room temperature ρ= 1000kg/m ³。

2. Head H

Head is the increase in energy per unit weight of liquid pumped by a water pump from the pump inlet (pump inlet flange) to the pump outlet (pump outlet flange).

That is, the effective energy obtained by one Newtonian liquid through a pump. Its unit is N · m/N=m, which is the height of the liquid column pumped by the pump, commonly referred to as meters.

3. Speed n

The rotational speed is the number of revolutions per unit time of the pump shaft, represented by the symbol n, in units of r/min.

4. NPSH

NPSH, also known as net positive suction head, is the main parameter that represents the cavitation performance. NPSH was previously expressed as △ h in China.

5. Power and efficiency

The power of a water pump usually refers to the input power, which is the power on the pump shaft transmitted by the prime mover, and is also known as shaft power, represented by P.

The effective power of a pump, also known as output power, is represented by Pe. It is the effective energy obtained by the liquid output from the pump per unit time in the pump.

Because head refers to the effective energy obtained by a unit of heavy liquid output from a pump, the product of head, mass flow rate, and gravitational acceleration is the effective energy obtained by the liquid output from the pump per unit time - that is, the effective power of the pump;

Pe= ρ GQH (W)= γ QH (W)

In the formula ρ—— The density of liquid conveyed by the pump (kg/m) ³);

γ—— The weight of liquid transported by the pump (N/m) ³);

Q - Pump flow rate (m) ³/ S)

H - Pump head (m):

G - Gravitational acceleration (m/s2);

The difference between the shaft power p and the effective power Pe is the power loss inside the pump, which is measured by the efficiency of the pump. The efficiency of a pump is the ratio of effective power to shaft power, using η To represent.

2. What is traffic? What letter is used to represent it? How to convert?

The volume of liquid discharged by a pump per unit time is called flow rate, which is expressed in Q and is measured in units of measurement;

Cubic meters per hour, during water transmission lines (m) ³/ h) , liters per second (I/S),

Cubic meters per hour, during water transmission lines (m) ³/ h) , liters per second (I/s), L/s=3.6m ³/ H=0.06m ³/ Min=60L/min, G=Q ρ, G is the weight, ρ Is the specific gravity of the liquid.

For example, a pump with a flow rate of 50m ³/ h. What is the weight per hour when pumping water? Specific gravity of water ρ It is 1000 kilograms per cubic meter.

Solution: G=Q ρ= 50 x 1000 (m ³/ H · kg/m ³)= 50000kg/h=50t/h

3. What is lift? What letter is used to represent it? What unit of measurement is used? Conversion and formula with pressure?

The energy obtained per unit weight of liquid through a pump is called head. The head of the pump, including the suction head, is approximately the pressure difference between the outlet and inlet of the water pump.

The head is represented by H, in meters (m).

The pressure of the pump is expressed in P, in Mpa (megapascals), and H=P/ ρ、 If P is 1kg/c ㎡, then H=(1kg/c ㎡)/(1000kg/m ³) H=(1kg/c ㎡)/(1000 kg/m ³)= (10000 kg/㎡)/1000 kg/m ³= 10m 1Mpa=10kg/c ㎡, H=(P2-P1)/ ρ (P2=outlet pressure P1=inlet pressure)

4. What is cavitation margin? What is suction range? What are the letters used to represent each unit of measurement?

When a water pump is in operation, the liquid at the inlet of the impeller will generate vapor under a certain vacuum pressure. The vaporized bubbles will cause erosion on the metal surface of the impeller under the impact motion of the liquid particles, thereby damaging the impeller and other metals. At this time, the vacuum pressure is called vaporization pressure.

Cavitation margin refers to the excess energy per unit weight of liquid at the pump inlet that exceeds the vaporization pressure.

Units are marked in meters and expressed in (NPSH) r. The suction head is the necessary cavitation margin △ h, which is the vacuum degree that the pump is allowed to suction liquid, that is, the installation height allowed by the pump, in meters.

Suction lift=standard atmospheric pressure (10, 33 meters) - NPSH - safety margin (0.5 meters)

The standard atmospheric pressure can pressure the vacuum height of the pipeline to 10 and 33 meters.

For example, for a certain pump, the required NPSH is 4.0 meters. Can we calculate the suction head △ h?

Solution: Δ h=10, 33-4, 0-0, 5-5, 83 meters.